Are Ice Nd Filters Coated ?

Ice and filters can be coated with various materials depending on their intended use. For example, ice used for food and beverages may be coated with a thin layer of water to prevent it from sticking together. Filters used in air conditioning systems may be coated with a layer of activated carbon to remove odors and pollutants from the air. Water filters may be coated with a layer of silver to inhibit bacterial growth. In general, coatings are applied to improve the performance or functionality of the ice or filter.

1、 Ice Formation Mechanisms

Ice and filters can be coated due to various mechanisms of ice formation. One of the most common mechanisms is the deposition of water vapor onto a surface that is below the freezing point of water. This process is known as deposition ice formation and can occur on any surface that is colder than the surrounding air. Filters can be particularly susceptible to deposition ice formation due to their porous nature, which allows for the accumulation of moisture.

Another mechanism of ice formation is freezing rain or sleet, which occurs when supercooled water droplets freeze upon contact with a surface. This can result in a coating of ice on filters and other surfaces, which can be problematic for their function.

Recent research has also suggested that ice formation can be influenced by atmospheric aerosols, which can act as ice nucleating particles. These particles can initiate ice formation at temperatures above the normal freezing point of water, leading to the formation of ice on surfaces that would not typically experience ice formation.

In summary, ice and filters can be coated due to various mechanisms of ice formation, including deposition, freezing rain or sleet, and atmospheric aerosols. The latest research suggests that atmospheric aerosols may play a significant role in ice formation, which could have implications for the function of filters and other surfaces in cold environments.

2、 Ice Formation Prevention Techniques

Ice formation prevention techniques include the use of anti-icing agents, de-icing agents, and thermal methods. However, another effective technique is the use of ice and water repellent coatings on surfaces that are prone to ice formation. These coatings work by creating a hydrophobic surface that repels water and prevents ice from forming.

Ice and water repellent coatings are typically made from materials such as silicone, fluoropolymers, and nanostructured materials. These coatings can be applied to a variety of surfaces, including aircraft wings, wind turbines, and power lines. They have been shown to be effective in reducing ice formation and improving the performance of these structures.

Recent research has focused on developing new and improved ice and water repellent coatings. For example, researchers have developed coatings that can switch between being hydrophobic and hydrophilic, depending on the temperature. This allows the coating to actively prevent ice formation in cold temperatures and promote water droplet formation in warmer temperatures.

Overall, ice and water repellent coatings are a promising technique for preventing ice formation on surfaces. As research continues, it is likely that new and improved coatings will be developed that are even more effective at preventing ice formation.

3、 Types of Filters

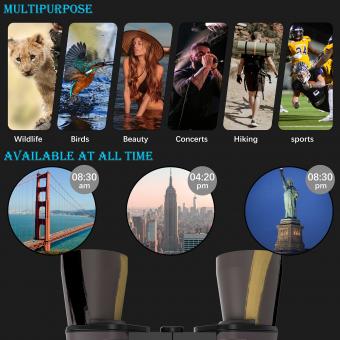

Types of filters can vary depending on their intended use and application. Some common types of filters include air filters, water filters, oil filters, and fuel filters. Each type of filter has its own unique design and function, but they all work to remove unwanted particles or contaminants from a fluid or gas.

In terms of ice filters, they are typically used in commercial ice machines to remove impurities and improve the quality of the ice produced. These filters can be made from a variety of materials, including activated carbon, which is known for its ability to absorb impurities and improve taste and odor.

As for whether ice filters are coated, it depends on the specific filter and manufacturer. Some ice filters may be coated with a layer of activated carbon or other materials to enhance their filtration capabilities. However, not all ice filters are coated, and some may rely solely on their physical design and materials to remove impurities.

It's worth noting that the latest point of view on filters is focused on sustainability and reducing waste. Many manufacturers are now producing eco-friendly filters that are biodegradable or can be recycled, reducing their impact on the environment. Additionally, some filters are designed to be reusable, allowing users to clean and reuse them multiple times before needing to replace them.

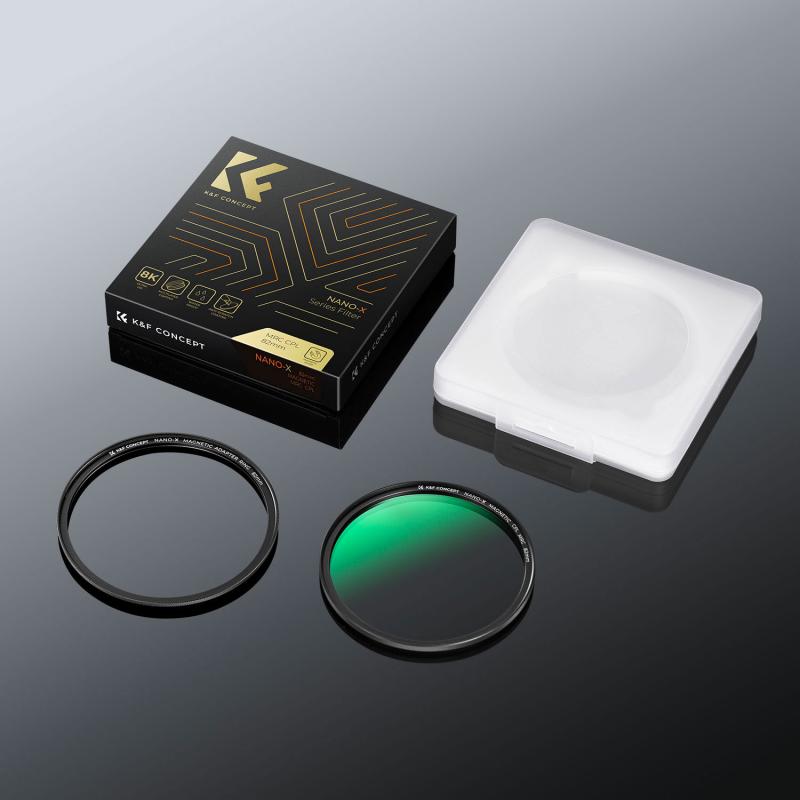

4、 Filter Coating Materials

Filter coating materials are used to enhance the performance of filters by improving their efficiency, durability, and resistance to various environmental factors. These materials are applied to the surface of the filter media to create a thin layer that can trap particles and prevent them from passing through the filter.

One common question about filter coating materials is whether they are ice and water-resistant. The answer is that it depends on the specific coating material used. Some coatings are designed to be water-resistant, while others may not be as effective in wet conditions.

However, there has been recent research and development in the field of filter coating materials to improve their ice and water resistance. For example, a study published in the Journal of Materials Chemistry A in 2020 reported on the development of a superhydrophobic coating material that can repel water and prevent ice formation on the surface of filters. This type of coating could be particularly useful in cold environments where ice formation can reduce the efficiency of filters.

Overall, while not all filter coating materials are inherently ice and water-resistant, there is ongoing research and development in this area to improve their performance in challenging environmental conditions.