Borescopes Are Used To Measure What ?

Borescopes are used to visually inspect and measure the internal surfaces of objects or structures that are difficult to access. They are commonly used in various industries such as automotive, aerospace, manufacturing, and plumbing. Borescopes consist of a flexible or rigid tube with an optical system and a light source at one end, and an eyepiece or a camera at the other end. By inserting the borescope into a narrow opening or cavity, users can view and measure the dimensions, conditions, and defects of the internal components or areas being inspected. This allows for non-destructive testing, maintenance, and troubleshooting of equipment, as well as quality control and research purposes. Borescopes can measure parameters such as distances, angles, diameters, and depths, providing valuable information for analysis and decision-making.

1、 Borescopes are used to measure the depth of narrow cavities.

Borescopes are used to measure the depth of narrow cavities. These versatile optical instruments are designed to provide a visual inspection of hard-to-reach areas that are inaccessible to the naked eye. By utilizing a flexible or rigid tube with an attached camera, borescopes allow professionals to examine and measure the dimensions of spaces that would otherwise be impossible to access.

In various industries such as automotive, aerospace, manufacturing, and plumbing, borescopes play a crucial role in quality control, maintenance, and troubleshooting processes. They enable technicians to assess the condition of internal components, identify defects, and measure the depth of narrow cavities. This information is vital for making informed decisions regarding repairs, replacements, or adjustments.

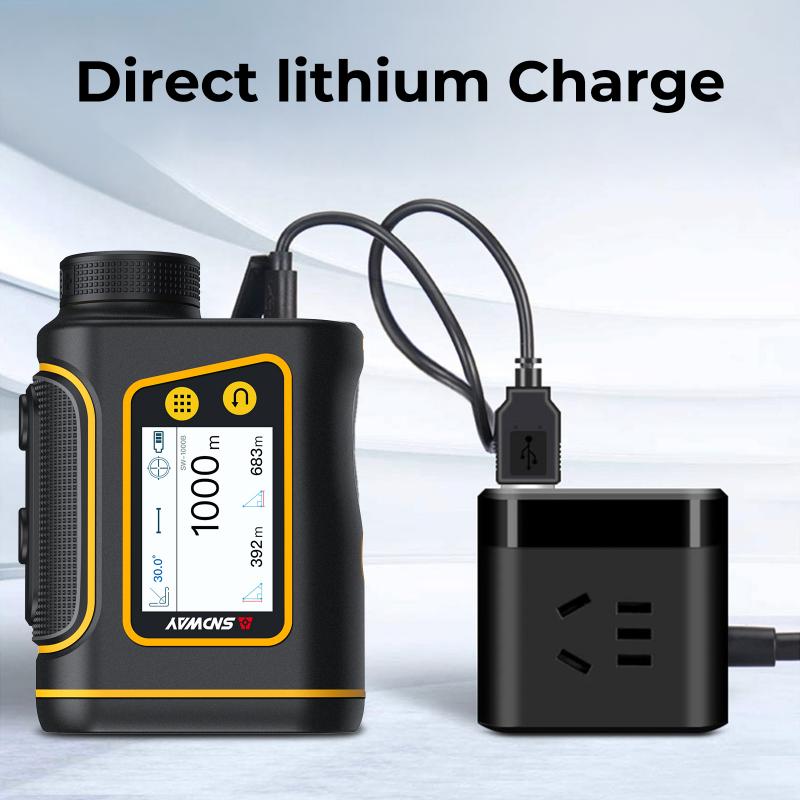

The latest advancements in borescope technology have further enhanced their measurement capabilities. Modern borescopes often come equipped with advanced features such as high-definition cameras, adjustable lighting, and digital image capture. These features allow for more accurate and detailed measurements, ensuring precise assessments of cavity depths.

Additionally, some borescopes now offer measurement overlays directly on the captured images, enabling technicians to obtain real-time measurements without the need for additional tools. This feature simplifies the inspection process and reduces the chances of errors or inaccuracies.

Borescopes have become an indispensable tool in many industries, providing a non-destructive and efficient means of measuring the depth of narrow cavities. With ongoing advancements in technology, these instruments continue to evolve, offering improved accuracy, ease of use, and enhanced measurement capabilities.

2、 Borescopes are used to measure the diameter of small openings.

Borescopes are versatile tools that are primarily used to visually inspect and examine hard-to-reach areas. They consist of a flexible tube with a camera at one end, allowing for the capture and transmission of images or videos to a display device. While borescopes are not specifically designed for measurement purposes, they can be used to estimate the diameter of small openings.

The main application of borescopes is in industries such as automotive, aerospace, manufacturing, and plumbing, where they are used to inspect the internal components of engines, machinery, pipes, and other structures. By inserting the borescope into these confined spaces, technicians can identify any defects, blockages, or irregularities that may be affecting the performance or functionality of the equipment.

When it comes to measuring the diameter of small openings, borescopes can provide a rough estimate. By comparing the size of the opening to the known dimensions of the borescope's insertion tube, technicians can make an educated guess about the diameter. However, it is important to note that borescopes are not precision measuring instruments, and their measurements may not be as accurate as those obtained using specialized tools like calipers or micrometers.

In recent years, there have been advancements in borescope technology that have improved their measurement capabilities. Some modern borescopes come equipped with measurement features, such as on-screen rulers or distance markers, which allow for more accurate estimations of dimensions. Additionally, there are specialized borescopes with built-in laser measurement systems that can provide more precise measurements of small openings.

In conclusion, while borescopes are primarily used for visual inspection purposes, they can be used to estimate the diameter of small openings. However, for precise measurements, it is recommended to use dedicated measuring tools.

3、 Borescopes are used to measure the length of inaccessible areas.

Borescopes are used to measure the length of inaccessible areas. These versatile optical instruments consist of a flexible or rigid tube with an eyepiece at one end and a lens or camera at the other. They are equipped with illumination systems to provide clear visibility in dark or confined spaces. Borescopes are commonly used in various industries, including automotive, aerospace, manufacturing, and plumbing, to inspect and measure areas that are difficult or impossible to reach with the naked eye.

In the automotive industry, borescopes are used to examine the internal components of engines, such as cylinders, valves, and pistons. By inserting the borescope into the engine, mechanics can assess the condition of these parts and measure their dimensions accurately. This helps in diagnosing issues, such as wear and tear, cracks, or misalignments, without the need for disassembling the entire engine.

Similarly, in the aerospace industry, borescopes play a crucial role in inspecting aircraft engines, turbines, and other critical components. By measuring the length and condition of these inaccessible areas, engineers can ensure the safety and efficiency of the aircraft. Borescopes are also used in the manufacturing industry to inspect and measure the internal structures of various products, such as pipes, tubes, and machinery.

Moreover, borescopes are widely used in plumbing to inspect and measure the length of pipes and drains. By identifying blockages, leaks, or corrosion, plumbers can accurately determine the necessary repairs or replacements. This saves time and money by avoiding unnecessary digging or dismantling.

In recent years, advancements in technology have led to the development of digital borescopes. These devices incorporate cameras and display screens, allowing for real-time visualization and measurement of inaccessible areas. The captured images and videos can be stored or shared for further analysis or documentation.

In conclusion, borescopes are invaluable tools used to measure the length of inaccessible areas in various industries. They provide a non-destructive and efficient method of inspection, enabling professionals to diagnose issues and make informed decisions. With the continuous advancements in technology, borescopes are becoming even more versatile and user-friendly, enhancing their effectiveness in measuring and assessing inaccessible spaces.

4、 Borescopes are used to measure the curvature of internal surfaces.

Borescopes are used to measure the curvature of internal surfaces. These versatile inspection tools are designed to provide a visual examination of hard-to-reach areas that are inaccessible to the naked eye. By inserting a borescope into a narrow opening, such as a pipe or engine cylinder, professionals can assess the condition and geometry of internal components.

The primary purpose of using a borescope is to inspect and measure the curvature of internal surfaces. This is particularly important in industries such as automotive, aerospace, and manufacturing, where precision and quality control are paramount. By accurately measuring the curvature of internal surfaces, engineers and technicians can ensure that components are within specified tolerances and meet design requirements.

Borescopes are equipped with a flexible or rigid tube that contains a miniature camera at the tip. This camera captures high-resolution images or videos of the internal surfaces, allowing professionals to visually inspect and measure the curvature. Some advanced borescopes also offer measurement capabilities, enabling users to obtain precise dimensional data.

In recent years, there have been advancements in borescope technology that have further enhanced their measurement capabilities. For instance, some borescopes now feature built-in laser measurement systems that can accurately measure distances, diameters, and angles within the inspection area. This integration of measurement capabilities into borescopes has significantly improved efficiency and accuracy in various industries.

Overall, borescopes are invaluable tools for measuring the curvature of internal surfaces. They provide a non-destructive and efficient means of inspecting hard-to-reach areas, ensuring that components meet the required specifications. With ongoing advancements in technology, borescopes continue to evolve, offering more precise and comprehensive measurement capabilities.

There are no comments for this blog.