How Is A Polarizing Filter Made ?

A polarizing filter is made by embedding a sheet of polarizing material between two layers of optical glass or plastic. The polarizing material is typically made of a long chain polymer that has been stretched and aligned in a specific direction. This alignment causes the material to absorb light waves that are oscillating in certain directions, while allowing light waves that are oscillating in other directions to pass through.

The polarizing material is typically made from a synthetic polymer such as polyvinyl alcohol (PVA) or polyethylene terephthalate (PET). The material is stretched in one direction to create a long chain polymer with a uniform alignment of molecules. This material is then sandwiched between two layers of optical glass or plastic to create a polarizing filter.

The orientation of the polarizing material can be adjusted by rotating the filter, which changes the direction of the polarized light that is allowed to pass through. This property makes polarizing filters useful in a variety of applications, including photography, microscopy, and LCD displays.

1、 Polarizing material selection

How is a polarizing filter made? The process of making a polarizing filter involves several steps, but the most critical step is the selection of the polarizing material. Polarizing materials are substances that can filter out light waves that vibrate in a particular direction. The most commonly used polarizing materials are polaroid sheets, which are made from a synthetic polymer called polyvinyl alcohol. These sheets are treated with iodine to create long chains of molecules that align in a specific direction.

Once the polarizing material is selected, it is then sandwiched between two layers of glass or plastic to create a polarizing filter. The filter is then coated with an anti-reflective coating to reduce glare and improve image quality. The thickness of the polarizing material and the angle at which it is placed between the layers of glass or plastic can affect the amount of light that is filtered out.

In recent years, there has been a growing interest in developing new types of polarizing materials that are more efficient and environmentally friendly. For example, researchers have developed polarizing materials made from cellulose nanocrystals, which are derived from renewable sources such as wood pulp. These materials have shown promising results in terms of their ability to filter out light waves and their potential for use in various applications, including displays and optical devices.

In conclusion, the process of making a polarizing filter involves selecting the right polarizing material and sandwiching it between layers of glass or plastic. With advancements in technology, new types of polarizing materials are being developed that offer improved efficiency and sustainability.

2、 Orientation of polarizing material

A polarizing filter is made by using a polarizing material that is oriented in a specific way. The material used is typically a thin film made of a polymer or a crystal, such as polyvinyl alcohol or iodine-doped polyvinyl alcohol. The orientation of the polarizing material is crucial to the filter's effectiveness in blocking certain types of light waves.

The polarizing material is typically stretched or aligned in a specific direction, which causes the material to absorb light waves that are oriented in a perpendicular direction. This creates a filter that only allows light waves that are oriented in a specific direction to pass through, while blocking all other light waves.

In recent years, there has been a growing interest in developing new types of polarizing materials that are more efficient and effective. Researchers have been exploring the use of nanotechnology to create polarizing materials that are thinner, lighter, and more durable than traditional materials. They have also been experimenting with new materials, such as graphene, that have unique properties that could make them ideal for use in polarizing filters.

Overall, the process of making a polarizing filter involves carefully selecting and orienting a polarizing material to create a filter that blocks unwanted light waves. As technology continues to advance, we can expect to see new and innovative approaches to creating polarizing filters that are even more effective and efficient than those currently available.

3、 Lamination of polarizing material

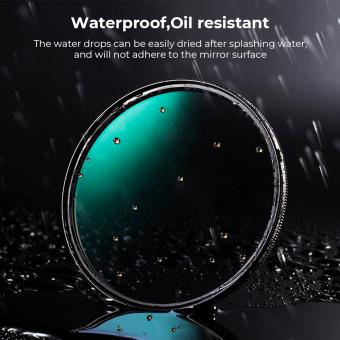

A polarizing filter is a type of optical filter that is used to reduce glare and improve the clarity of images. It works by selectively blocking certain polarized light waves while allowing others to pass through. This is achieved through the use of a special material that is laminated onto a glass or plastic substrate.

The polarizing material used in these filters is typically made from a polymer film that contains aligned molecules. When light passes through this material, the aligned molecules selectively absorb certain polarized light waves, while allowing others to pass through. This results in a reduction in glare and an improvement in image clarity.

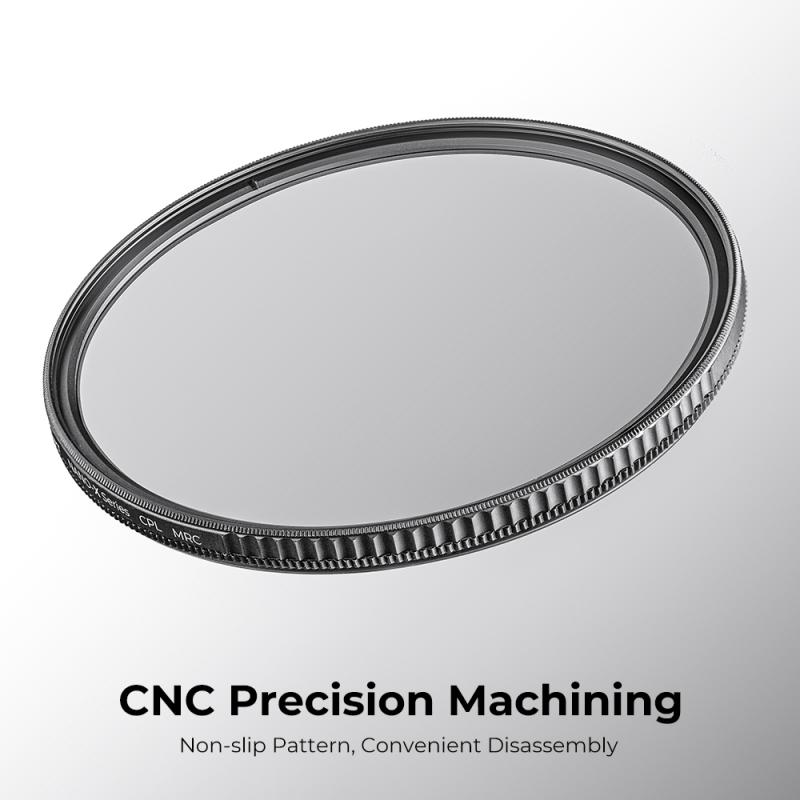

The process of making a polarizing filter involves laminating the polarizing material onto a glass or plastic substrate. This is typically done using a process called "dry lamination," which involves applying an adhesive layer to the substrate and then pressing the polarizing material onto it. The resulting filter is then cut to size and mounted in a frame or holder.

In recent years, there has been growing interest in the development of new types of polarizing materials that are more efficient and durable than traditional polymer films. For example, researchers have developed polarizing materials based on carbon nanotubes and other advanced materials that offer improved performance and durability. These new materials are expected to play an increasingly important role in the development of next-generation polarizing filters for a wide range of applications.

4、 Adhesive application

A polarizing filter is a type of optical filter that is used to reduce glare and improve the clarity of images. It works by selectively blocking certain polarized light waves, allowing only the desired light waves to pass through. The filter is made up of a thin layer of polarizing material that is sandwiched between two layers of glass or plastic.

The process of making a polarizing filter involves several steps, including adhesive application. The polarizing material is first coated with a layer of adhesive, which helps to bond it to the glass or plastic layers. The adhesive is carefully applied to ensure that it covers the entire surface of the polarizing material, without leaving any gaps or bubbles.

Once the adhesive has been applied, the polarizing material is sandwiched between the two layers of glass or plastic. The layers are then heated and pressed together, creating a strong bond between the polarizing material and the glass or plastic layers.

In recent years, there has been a growing interest in the development of new types of polarizing filters that are more efficient and cost-effective. One promising approach is the use of nanostructures, which can be used to create polarizing filters that are thinner, lighter, and more flexible than traditional filters. These new filters are also more environmentally friendly, as they can be produced using fewer materials and less energy than traditional filters.