How Is An Endoscope Made ?

An endoscope is typically made using a combination of materials such as stainless steel, optical fibers, lenses, and electronic components. The outer casing of the endoscope is usually made of stainless steel or a similar durable material to provide strength and protection. The optical fibers are used to transmit light from a source to illuminate the area being examined, while lenses help focus the light and provide magnification. Electronic components, such as a camera or sensors, may be integrated into the endoscope to capture images or gather additional data. The manufacturing process involves assembling these components, ensuring proper alignment and calibration, and testing the functionality of the endoscope before it is ready for use in medical procedures.

1、 Components and assembly process of an endoscope

Components and assembly process of an endoscope:

An endoscope is a medical device used to visualize internal organs and body cavities. It consists of several key components that work together to provide high-quality imaging and maneuverability. The assembly process of an endoscope involves intricate steps to ensure precision and reliability.

1. Optical System: The optical system is the heart of an endoscope. It includes a lens system, fiber optic cables, and a light source. The lens system captures images and transmits them through fiber optic cables to the eyepiece or camera. The light source illuminates the area being examined.

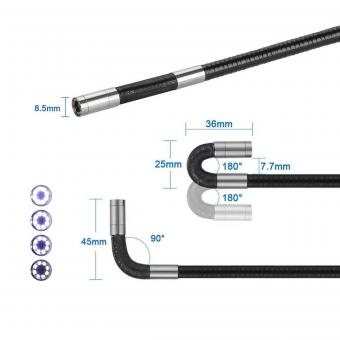

2. Insertion Tube: The insertion tube is a flexible or rigid tube that houses the optical system. It is typically made of medical-grade stainless steel or a durable polymer. The tube is designed to be flexible enough to navigate through the body's natural curves while maintaining its structural integrity.

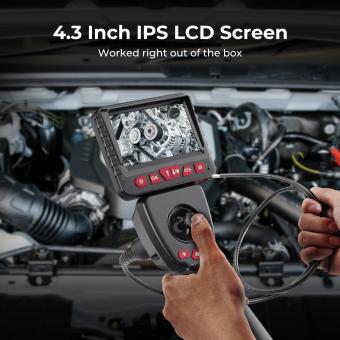

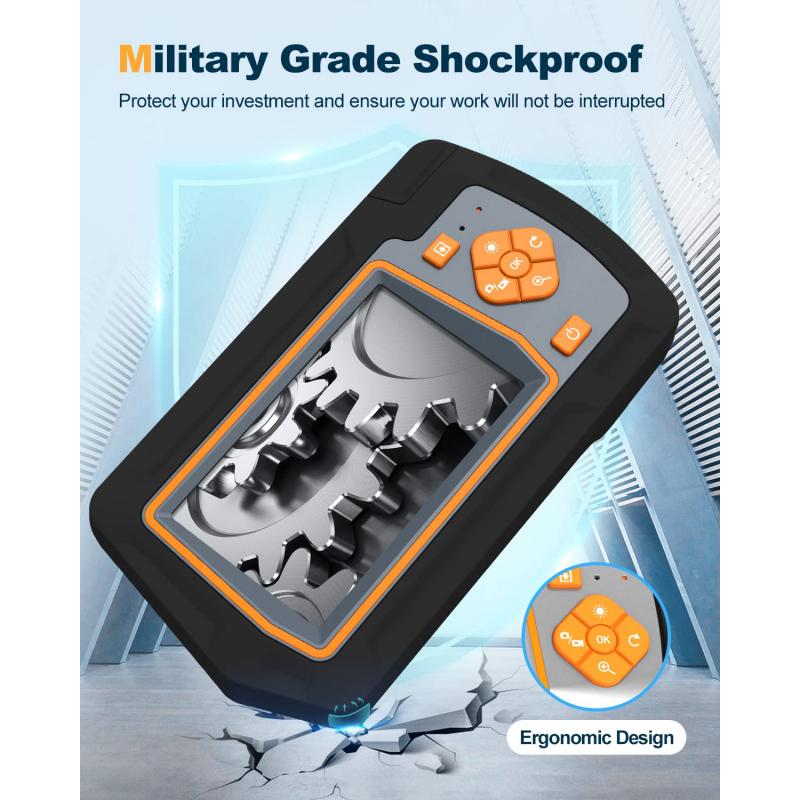

3. Control Section: The control section is where the user operates the endoscope. It contains buttons or knobs to control the direction and focus of the camera, as well as other functions such as suction or irrigation. The control section is usually ergonomically designed for ease of use.

4. Distal End: The distal end of the endoscope is the tip that enters the body. It is equipped with a camera or an eyepiece, as well as additional features like biopsy forceps or a suction channel. The distal end is often protected by a disposable sheath to prevent contamination.

The assembly process of an endoscope involves several steps. First, the optical system is carefully assembled, ensuring proper alignment and calibration. The insertion tube is then attached to the control section, and the distal end is connected to the insertion tube. Quality control checks are performed at each stage to ensure functionality and image quality.

In recent years, advancements in technology have led to the development of more compact and flexible endoscopes. Miniaturization of components and the use of advanced materials have allowed for improved maneuverability and patient comfort. Additionally, the integration of digital imaging and video capabilities has revolutionized endoscopy, enabling real-time visualization and documentation.

Overall, the manufacturing process of an endoscope requires precision engineering and adherence to strict quality standards. Continuous research and development efforts are focused on enhancing the performance, durability, and usability of endoscopes to improve patient outcomes and advance medical diagnostics and treatments.

2、 Materials used in endoscope manufacturing

An endoscope is a medical device used for visualizing and examining the internal organs and cavities of the human body. It is made using a combination of various materials and advanced manufacturing techniques.

The main components of an endoscope include the insertion tube, control section, and the distal tip. The insertion tube is typically made of a flexible material such as medical-grade silicone or polyurethane. These materials provide flexibility and durability, allowing the endoscope to navigate through the body's natural curves and bends.

The control section houses the various controls and mechanisms for manipulating the endoscope. It is usually made of lightweight metals such as aluminum or titanium, which provide strength and ease of handling. The distal tip, which contains the camera and illumination system, is typically made of stainless steel or high-quality plastics.

In recent years, there have been advancements in endoscope manufacturing, particularly in the materials used for the distal tip. Researchers have been exploring the use of biocompatible materials, such as biodegradable polymers, for the distal tip. These materials have the potential to reduce the risk of infection and improve patient comfort during endoscopic procedures.

Additionally, there has been a growing interest in the use of nanomaterials for endoscope manufacturing. Nanomaterials offer unique properties such as enhanced imaging capabilities and improved mechanical strength. For example, carbon nanotubes have been incorporated into endoscope components to enhance their electrical conductivity and imaging resolution.

Overall, the materials used in endoscope manufacturing are carefully selected to ensure the device's functionality, durability, and patient safety. Ongoing research and advancements in materials science continue to drive innovation in endoscope design and manufacturing, leading to improved diagnostic and therapeutic capabilities in the field of medical endoscopy.

3、 Optical system design and construction in endoscopes

An endoscope is a medical device used to visualize internal organs and body cavities. It consists of several components, with the optical system being a crucial part of its design and construction.

The optical system in an endoscope is responsible for capturing and transmitting high-quality images from the internal body to the external viewing system. It typically includes a lens system, fiber optic cables, and a camera or eyepiece for visualization. The lens system is designed to provide a wide field of view and high resolution, allowing for detailed examination of the target area.

The construction of the optical system involves precise assembly of the lenses and fiber optic cables. The lenses are carefully aligned to ensure optimal image quality and minimize distortion. The fiber optic cables are used to transmit light from an external source to illuminate the target area. These cables are made of flexible glass or plastic fibers that are bundled together and coated to protect them from damage.

In recent years, there have been advancements in endoscope technology, particularly in the field of miniaturization. Miniature endoscopes with smaller diameters have been developed, allowing for less invasive procedures. This has been made possible by advancements in lens and fiber optic technology, enabling the construction of smaller and more flexible optical systems.

Additionally, there have been developments in the use of digital imaging in endoscopes. Traditional endoscopes used analog cameras or eyepieces for visualization, but digital imaging technology has allowed for the integration of high-resolution cameras and advanced image processing algorithms. This has improved the quality of images captured by endoscopes and facilitated better diagnosis and treatment.

In conclusion, the design and construction of the optical system in an endoscope involve precise assembly of lenses and fiber optic cables. Recent advancements in technology have led to the development of smaller and more flexible endoscopes, as well as the integration of digital imaging for improved visualization. These advancements have significantly enhanced the capabilities of endoscopes and have contributed to better patient care.

4、 Integration of imaging technology in endoscope production

The production of an endoscope involves the integration of imaging technology to enable visualization and diagnosis of internal body parts. Endoscopes are medical devices used by healthcare professionals to examine the interior of a patient's body without the need for invasive surgery. They consist of a flexible or rigid tube with a light source and a camera at one end, which transmits real-time images to a monitor for analysis.

The manufacturing process of an endoscope begins with the selection of high-quality materials that are biocompatible and durable. The tube is typically made of medical-grade stainless steel or flexible fiber-optic bundles. The integration of imaging technology involves the incorporation of a high-resolution camera chip, lens system, and light source into the endoscope.

The camera chip is a crucial component that captures the images and transmits them to the monitor. In recent years, there have been advancements in camera chip technology, such as the development of smaller and more sensitive sensors, allowing for higher image quality and improved diagnostic capabilities. Additionally, the lens system plays a vital role in focusing the light onto the camera chip and ensuring clear and sharp images.

The light source is another critical aspect of endoscope production. Traditionally, endoscopes used external light sources, such as halogen or xenon lamps. However, there has been a shift towards integrating LED light sources directly into the endoscope. LED technology offers several advantages, including longer lifespan, lower power consumption, and improved color rendering.

Furthermore, the latest point of view in endoscope production involves the incorporation of advanced imaging technologies, such as high-definition (HD) and 3D imaging. HD endoscopes provide enhanced image resolution, allowing for better visualization of anatomical structures and abnormalities. 3D endoscopes offer depth perception, which can aid in surgical procedures and improve accuracy.

In conclusion, the production of an endoscope involves the integration of imaging technology, including camera chips, lens systems, and light sources. The latest advancements in this field have led to improved image quality, diagnostic capabilities, and the incorporation of HD and 3D imaging. These advancements continue to enhance the effectiveness and precision of endoscopic procedures, ultimately benefiting patient care.