How Lens Filters Are Made ?

Lens filters are made by sandwiching a piece of optical glass or plastic between two metal or plastic rings. The glass or plastic is carefully selected for its optical properties, such as its ability to block certain wavelengths of light or to enhance certain colors. The rings are typically made of aluminum or plastic and are designed to screw onto the front of a camera lens.

The glass or plastic is first cut to the desired size and shape using precision cutting tools. It is then polished to remove any imperfections and to ensure that it is perfectly flat and smooth. The rings are also cut and shaped to the correct size and threaded to match the lens they will be used with.

The glass or plastic is then carefully mounted between the rings using a special adhesive or by pressure fitting. The filter is then tested to ensure that it meets the required optical specifications and is free from defects. Once it has passed these tests, it is packaged and shipped to retailers or directly to customers.

1、 Materials used in lens filter production

Materials used in lens filter production include glass, plastic, and resin. Glass filters are made by cutting and polishing a piece of glass to the desired size and shape, then applying a coating to the surface to achieve the desired effect. Plastic filters are made by molding the plastic into the desired shape and then applying a coating to the surface. Resin filters are made by mixing a liquid resin with a hardener and pouring it into a mold to create the desired shape.

The coatings applied to lens filters can be made from a variety of materials, including metal oxides, dyes, and pigments. These coatings are designed to block certain wavelengths of light or enhance certain colors, depending on the desired effect.

In recent years, there has been a growing trend towards using environmentally-friendly materials in lens filter production. Some manufacturers are using recycled materials or biodegradable plastics to reduce their environmental impact. Additionally, some filters are now being made with coatings that are free from harmful chemicals such as lead and cadmium.

Overall, the materials used in lens filter production are constantly evolving as manufacturers seek to improve the quality and sustainability of their products.

2、 Manufacturing processes for lens filters

Manufacturing processes for lens filters involve several steps that are critical to producing high-quality filters. The first step is to select the appropriate materials for the filter. This includes choosing the right type of glass or plastic, as well as any coatings or other materials that may be needed to achieve the desired optical properties.

Once the materials have been selected, the next step is to shape and polish the filter. This is typically done using precision grinding and polishing equipment, which can produce filters with extremely precise dimensions and surface finishes.

After the filter has been shaped and polished, any necessary coatings or other treatments are applied. This may include anti-reflective coatings, color filters, or other specialized coatings that are designed to enhance the filter's performance in specific applications.

Finally, the filter is inspected and tested to ensure that it meets the required specifications. This may involve measuring its optical properties, checking for defects or imperfections, and verifying that it is compatible with the intended application.

In recent years, there has been growing interest in using advanced manufacturing techniques such as 3D printing to produce lens filters. While this technology is still in its early stages, it has the potential to revolutionize the way filters are made, allowing for greater customization and faster production times. However, traditional manufacturing processes are still widely used and are likely to remain the primary method for producing high-quality lens filters for the foreseeable future.

3、 Types of lens filters and their functions

Types of lens filters and their functions:

Lens filters are essential accessories for photographers and videographers. They are used to enhance the quality of images and videos by controlling light, reducing glare, and adding special effects. Here are some of the most common types of lens filters and their functions:

1. UV Filters: These filters are used to reduce the amount of ultraviolet light that enters the lens. They are particularly useful when shooting in bright sunlight, as they can help to reduce haze and improve contrast.

2. Polarizing Filters: These filters are used to reduce glare and reflections from non-metallic surfaces such as water, glass, and foliage. They can also help to enhance the color saturation of the image.

3. Neutral Density Filters: These filters are used to reduce the amount of light that enters the lens, allowing for longer exposure times or wider apertures. They are particularly useful for landscape photography and long exposure shots.

4. Graduated Filters: These filters are used to balance the exposure between the sky and the foreground in landscape photography. They are available in both hard and soft transitions.

5. Special Effects Filters: These filters are used to add creative effects to images, such as starbursts, soft focus, and diffusion.

How lens filters are made:

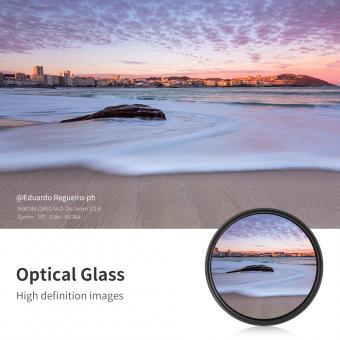

Lens filters are typically made from high-quality optical glass or resin. The glass is ground and polished to precise specifications, and then coated with multiple layers of anti-reflective coatings to reduce glare and improve image quality. The coatings are applied using a vacuum deposition process, which involves heating the glass and evaporating the coating material in a vacuum chamber. The coated glass is then cut to size and mounted in a filter ring, which is typically made from aluminum or plastic. Some filters may also include additional features such as weather sealing or anti-static coatings. In recent years, there has been a trend towards using more environmentally friendly materials in filter production, such as bio-based plastics and recycled materials.

4、 Quality control measures for lens filters

Quality control measures for lens filters are essential to ensure that the filters meet the required standards and specifications. The manufacturing process of lens filters involves several steps, including the selection of raw materials, cutting, polishing, coating, and packaging. Each of these steps requires strict quality control measures to ensure that the final product is of high quality.

One of the critical quality control measures for lens filters is the inspection of raw materials. The materials used in the manufacturing process must meet the required specifications and standards. The raw materials are inspected for defects, such as scratches, cracks, and impurities, which can affect the quality of the final product.

Another quality control measure is the inspection of the cutting and polishing process. The filters must be cut and polished to the required size and shape, and the surface must be smooth and free of defects. The filters are inspected for scratches, chips, and other defects that can affect the optical performance.

Coating is another critical step in the manufacturing process of lens filters. The coating must be applied evenly and must meet the required specifications. The filters are inspected for coating defects, such as bubbles, streaks, and unevenness.

Finally, the packaging process is also subject to quality control measures. The filters must be packaged in a way that protects them from damage during transportation and storage. The packaging must also be labeled correctly, indicating the type of filter and its specifications.

In conclusion, quality control measures are essential in the manufacturing process of lens filters. The filters must meet the required standards and specifications to ensure that they perform optimally. The latest point of view is that advancements in technology have made it possible to automate some of the quality control measures, such as inspection and testing, leading to increased efficiency and accuracy.

There are no comments for this blog.