Metal Detector Which ?

A metal detector is an electronic device used to detect the presence of metal objects. It works by generating a magnetic field and then measuring any disturbances in that field caused by nearby metal objects. Metal detectors are commonly used in a variety of applications, including security screening at airports and other public places, archaeological excavations, and treasure hunting. They can detect a wide range of metals, including iron, steel, aluminum, and precious metals like gold and silver. Metal detectors consist of a control box, which houses the circuitry and controls, and a search coil, which is the part that actually detects the metal. When the search coil comes into contact with a metal object, it sends a signal to the control box, which then alerts the user with a visual or audible indication. Metal detectors are a valuable tool in many industries and hobbies, helping to locate hidden or buried metal objects quickly and efficiently.

1、 Technology and Operation of Metal Detectors

Metal detectors are devices that use electromagnetic fields to detect the presence of metal objects. They are widely used in various industries and applications, including security screening, archaeology, and treasure hunting. The technology and operation of metal detectors have evolved significantly over the years, incorporating advanced features and techniques to improve their performance and accuracy.

One of the key advancements in metal detector technology is the use of multiple frequency detection. Traditional metal detectors operate at a single frequency, which limits their ability to detect different types of metals. However, modern metal detectors can operate at multiple frequencies simultaneously, allowing them to detect a wider range of metals with greater accuracy. This is particularly useful in security screening applications, where the detection of specific types of metals, such as weapons or explosives, is crucial.

Another important development in metal detector technology is the incorporation of digital signal processing. This technology allows metal detectors to analyze and interpret the signals received from the electromagnetic field, enhancing their ability to discriminate between different types of metals and reject false alarms. Digital signal processing also enables metal detectors to provide more detailed information about the detected metal objects, such as their size, shape, and composition.

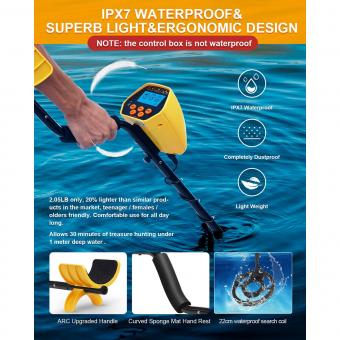

Furthermore, advancements in materials and design have led to the development of more lightweight and portable metal detectors. This has made them more accessible and convenient for various applications, such as outdoor activities like treasure hunting or metal detecting hobbies.

In recent years, there has been a growing interest in the use of artificial intelligence and machine learning algorithms in metal detector technology. These techniques can improve the detection accuracy by learning from past data and adapting to different environments and conditions. Additionally, the integration of wireless connectivity and smartphone applications has made it easier to control and monitor metal detectors remotely.

Overall, the technology and operation of metal detectors have come a long way, offering improved performance, versatility, and convenience. With ongoing research and development, we can expect further advancements in the future, making metal detectors even more effective and efficient in their applications.

2、 Types and Applications of Metal Detectors

Metal detectors are devices that use electromagnetic fields to detect the presence of metal objects. They are widely used in various applications, ranging from security screening to treasure hunting and archaeological excavations. There are several types of metal detectors available, each with its own unique features and applications.

One type of metal detector is the beat frequency oscillator (BFO) detector. This type of detector uses two coils, one to transmit a continuous wave of electromagnetic energy and the other to receive the reflected signal. When the transmitted wave encounters a metal object, it disrupts the frequency of the received signal, indicating the presence of metal.

Another type is the very low frequency (VLF) detector, which is the most common type used today. VLF detectors use two coils as well, but they operate at different frequencies. The difference in frequency between the two coils creates a magnetic field that is sensitive to metal objects. VLF detectors are known for their ability to discriminate between different types of metals, making them ideal for coin and relic hunting.

Pulse induction (PI) detectors are another type commonly used in industrial and underwater applications. These detectors send short bursts of current through a coil, creating a magnetic field. When a metal object is present, it disrupts the magnetic field, generating a pulse that is detected by the receiver coil. PI detectors are known for their ability to penetrate mineralized soil and are often used in beach and underwater treasure hunting.

In recent years, advancements in technology have led to the development of new types of metal detectors. For example, multi-frequency detectors are becoming increasingly popular. These detectors can operate at multiple frequencies simultaneously, allowing for improved target identification and depth detection.

Additionally, there has been a rise in the use of handheld and portable metal detectors for security screening purposes. These detectors are commonly used in airports, schools, and public venues to detect weapons and other metallic threats.

In conclusion, metal detectors have a wide range of applications and come in various types to suit different needs. From BFO and VLF detectors for hobbyists to PI detectors for industrial use, the technology continues to evolve, offering improved performance and functionality. With the latest advancements, metal detectors are becoming more efficient, accurate, and user-friendly, making them an essential tool in various industries and recreational activities.

3、 Principles of Electromagnetic Induction in Metal Detection

The principles of electromagnetic induction in metal detection are the foundation of metal detectors, which are widely used in various industries and applications. Metal detectors work based on the principle that when a metal object passes through a magnetic field, it induces an electric current in the object. This current, in turn, generates a secondary magnetic field that can be detected by the metal detector.

Metal detectors consist of a transmitter coil and a receiver coil. The transmitter coil generates a magnetic field, while the receiver coil detects any changes in the magnetic field caused by the presence of a metal object. When a metal object enters the magnetic field, it disrupts the field and induces a current in the object. This current creates a secondary magnetic field that is detected by the receiver coil.

The latest point of view in metal detection technology involves advancements in coil design and signal processing algorithms. Coil design plays a crucial role in the sensitivity and accuracy of metal detectors. New coil designs focus on improving the detection depth and target separation capabilities of metal detectors.

Signal processing algorithms have also evolved to enhance the performance of metal detectors. Advanced algorithms can analyze the received signals and differentiate between different types of metals, allowing for more precise identification and discrimination. Additionally, these algorithms can filter out unwanted signals from environmental noise, improving the overall reliability of metal detectors.

In conclusion, the principles of electromagnetic induction in metal detection form the basis of metal detectors. With advancements in coil design and signal processing algorithms, metal detectors have become more sensitive, accurate, and reliable. These advancements have expanded the applications of metal detectors in industries such as security, mining, archaeology, and food processing.

4、 Factors Affecting Metal Detection Performance

Factors Affecting Metal Detection Performance

Metal detection performance can be influenced by various factors, including:

1. Metal composition: The type of metal being detected can greatly impact the detection performance. Some metals, such as iron and steel, are easily detectable, while others, like aluminum and stainless steel, can be more challenging to detect due to their low magnetic properties.

2. Metal size and shape: The size and shape of the metal object can affect detection performance. Larger objects are generally easier to detect than smaller ones, and irregularly shaped objects may be more difficult to detect accurately.

3. Metal orientation: The orientation of the metal object in relation to the metal detector can affect detection performance. Objects that are perpendicular to the detector's coil are more easily detected than those that are parallel or at an angle.

4. Environmental factors: Environmental conditions, such as temperature, humidity, and electromagnetic interference, can impact metal detection performance. Extreme temperatures or high levels of humidity can affect the sensitivity and stability of the metal detector. Electromagnetic interference from nearby electrical equipment or other metal objects can also interfere with detection accuracy.

5. Sensitivity settings: The sensitivity settings of the metal detector can be adjusted to optimize detection performance. Higher sensitivity settings can detect smaller metal objects but may also increase the likelihood of false alarms. Finding the right balance between sensitivity and false alarms is crucial for effective metal detection.

6. Technology advancements: The latest advancements in metal detection technology can also impact performance. For example, newer metal detectors may incorporate advanced signal processing algorithms or multi-frequency capabilities, which can improve detection accuracy and reduce false alarms.

It is important to note that these factors are interrelated and can vary depending on the specific metal detector model and application. Regular calibration, maintenance, and operator training are essential to ensure optimal metal detection performance.