What Is Metallurgical Microscope ?

A metallurgical microscope is a type of microscope specifically designed for the examination of metal samples. It is used in the field of metallurgy to study the microstructure and composition of metals and alloys. This type of microscope is equipped with specialized features that allow for the observation of opaque samples, such as polished metal surfaces. It typically has a reflected light illumination system, which directs light onto the sample from above, and an objective lens that is positioned above the sample. Metallurgical microscopes often have high magnification capabilities and are equipped with polarizers and filters to enhance contrast and reveal specific features of the metal's microstructure. They are commonly used in materials science research, quality control, and failure analysis in industries such as automotive, aerospace, and manufacturing.

1、 Optical principles and components of a metallurgical microscope

A metallurgical microscope is a specialized type of microscope used in the field of metallurgy to examine the microstructure of metallic materials. It is designed to provide high magnification and resolution, allowing for detailed analysis of the internal structure of metals and alloys.

The optical principles and components of a metallurgical microscope are similar to those of a conventional light microscope. However, there are some key differences that make it suitable for metallurgical applications. One of the main differences is the use of reflected light instead of transmitted light. This is because metals are opaque and do not allow light to pass through them. Reflected light is directed onto the sample, and the resulting image is observed through the eyepiece or captured using a camera.

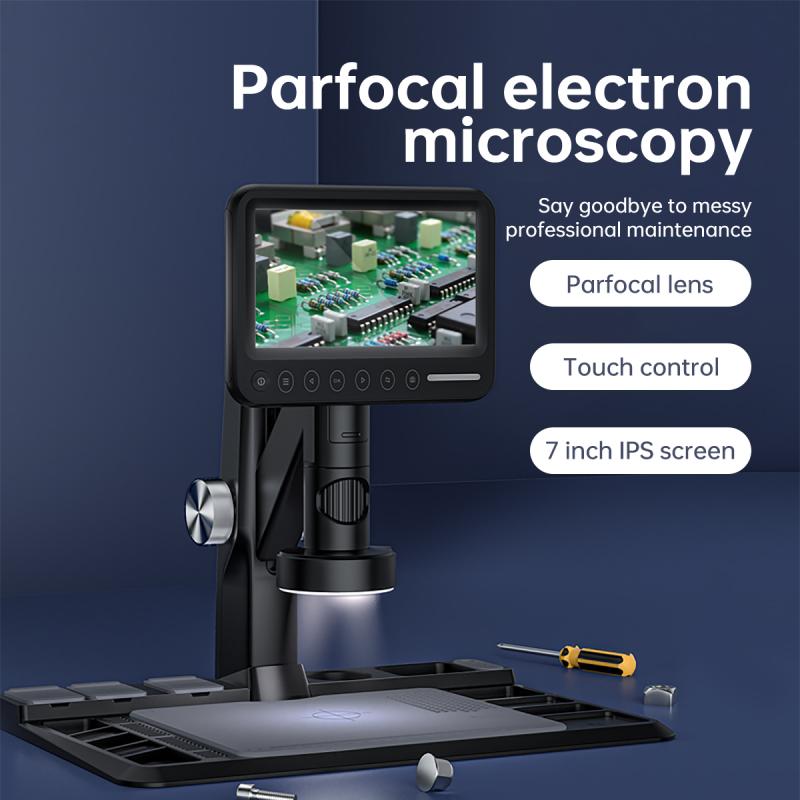

The components of a metallurgical microscope include an objective lens, an eyepiece, a light source, and a stage for holding the sample. The objective lens is specially designed to provide high magnification and resolution, allowing for detailed examination of the microstructure. The light source is typically a halogen lamp or LED, which provides bright and uniform illumination. The stage allows for precise positioning of the sample, and may also include features such as a rotating polarizer or filters for specialized imaging techniques.

In recent years, there have been advancements in metallurgical microscopy, particularly in the area of digital imaging. Many metallurgical microscopes now come equipped with digital cameras, allowing for the capture of high-resolution images and videos. This enables researchers to document and analyze the microstructure of metallic materials more efficiently. Additionally, there have been developments in software that can analyze the captured images, providing quantitative data on grain size, phase distribution, and other microstructural features.

Overall, a metallurgical microscope is a powerful tool in the field of metallurgy, enabling researchers to study the microstructure of metals and alloys in detail. With advancements in digital imaging and analysis, it continues to play a crucial role in materials science and engineering.

2、 Sample preparation techniques for metallurgical microscopy

A metallurgical microscope, also known as a metallographic microscope, is a specialized type of microscope used for the examination and analysis of metallic materials. It is designed to provide high magnification and resolution, allowing for detailed observation of the microstructure of metals and alloys.

Metallurgical microscopes are commonly used in materials science and engineering, as well as in industries such as manufacturing, aerospace, automotive, and metallurgy. They play a crucial role in quality control, research, and development processes, as they enable the examination of the internal structure of metals to assess their mechanical properties, composition, and overall quality.

Sample preparation techniques for metallurgical microscopy are essential to obtain accurate and reliable results. These techniques involve several steps, including cutting, mounting, grinding, polishing, and etching of the metal sample. Cutting is performed to obtain a representative section of the material, which is then mounted in a resin or metallographic mount to provide stability during the subsequent steps. Grinding and polishing are carried out to remove surface imperfections and create a smooth, flat surface for observation. Etching is often used to reveal the microstructure by selectively attacking certain phases or constituents of the metal.

In recent years, there have been advancements in sample preparation techniques for metallurgical microscopy. For instance, automated systems have been developed to streamline the process, reducing human error and increasing efficiency. Additionally, new etching solutions and methods have been introduced to enhance the contrast and reveal finer details of the microstructure. Furthermore, digital imaging and image analysis techniques have been integrated with metallurgical microscopes, allowing for quantitative analysis and documentation of the observed microstructures.

Overall, the metallurgical microscope and sample preparation techniques are crucial tools in the field of materials science, enabling researchers and engineers to gain valuable insights into the structure and properties of metallic materials. The continuous advancements in these techniques contribute to the improvement of material characterization and the development of new and innovative metal alloys.

3、 Observation and analysis of microstructures in metallurgical samples

A metallurgical microscope is a specialized type of microscope used for the observation and analysis of microstructures in metallurgical samples. It is designed to provide high magnification and resolution, allowing for detailed examination of the internal structure of metals and alloys.

Metallurgical microscopes are commonly used in materials science and engineering, as well as in the field of metallurgy. They are particularly useful for studying the microstructural features of metals, such as grain size, phase distribution, and the presence of defects or impurities. This information is crucial for understanding the mechanical, thermal, and chemical properties of metals, and for evaluating their suitability for specific applications.

The latest advancements in metallurgical microscopy have focused on improving image quality, ease of use, and data analysis capabilities. Modern metallurgical microscopes often incorporate advanced imaging techniques, such as polarized light microscopy, darkfield microscopy, and differential interference contrast microscopy. These techniques enhance the contrast and visibility of microstructural features, allowing for more accurate and detailed analysis.

Furthermore, digital imaging and image analysis software have revolutionized the field of metallurgical microscopy. These tools enable automated measurement and analysis of microstructural features, saving time and improving accuracy. They also facilitate the comparison and sharing of data, promoting collaboration and knowledge exchange among researchers and engineers.

In conclusion, a metallurgical microscope is a powerful tool for the observation and analysis of microstructures in metallurgical samples. With the latest advancements in imaging techniques and data analysis capabilities, metallurgical microscopy continues to play a crucial role in materials science and engineering, enabling the development of new and improved metal alloys for various applications.

4、 Polarized light microscopy in metallurgical analysis

A metallurgical microscope is a specialized type of microscope used in metallurgical analysis to examine the microstructure of metallic materials. It is designed to provide high magnification and resolution, allowing for detailed observation of the internal structure of metals and alloys.

Metallurgical microscopes are equipped with various features that make them suitable for analyzing metallic materials. They typically have a reflected light illumination system, which allows for the examination of opaque samples. This illumination method involves directing light onto the sample from above and observing the reflected light. The microscope also has a range of objective lenses with different magnification levels, enabling the user to zoom in and examine the sample at various levels of detail.

One important technique used in metallurgical analysis is polarized light microscopy. This technique involves the use of polarized light to examine the optical properties of metallic materials. By passing polarized light through the sample and analyzing how it interacts with the material, valuable information about the microstructure, grain boundaries, and defects can be obtained. Polarized light microscopy can also be used to identify and characterize different phases within the material.

In recent years, advancements in metallurgical microscopy have focused on improving image quality and enhancing the capabilities of the microscope. Digital imaging systems have been integrated into metallurgical microscopes, allowing for the capture and analysis of high-resolution images. Additionally, software tools have been developed to aid in image analysis and quantification of microstructural features.

Overall, metallurgical microscopes, including those equipped with polarized light microscopy capabilities, play a crucial role in the analysis and understanding of metallic materials. They provide valuable insights into the microstructure and properties of metals and alloys, aiding in the development of new materials and the improvement of existing ones.